Location

English- - -

- English

- Suomi

- Français

- Deutsch

- Ελληνικά

- Italiano

- 日本語

- Русский

- Español

- اللغة العربية

- Bahasa Melayu

- ภาษาไทย

- Filipino

- Bahasa Indonesia

- Norsk

- Svenska

- Dansk

- Português

- Čeština

- magya

- Polski

- limba română

Currency

- 0

Your cart is currently empty.

Continue shopping >

What is a COB LED light strip?

·Ocona·COB LED strip introductionWhat is COB?

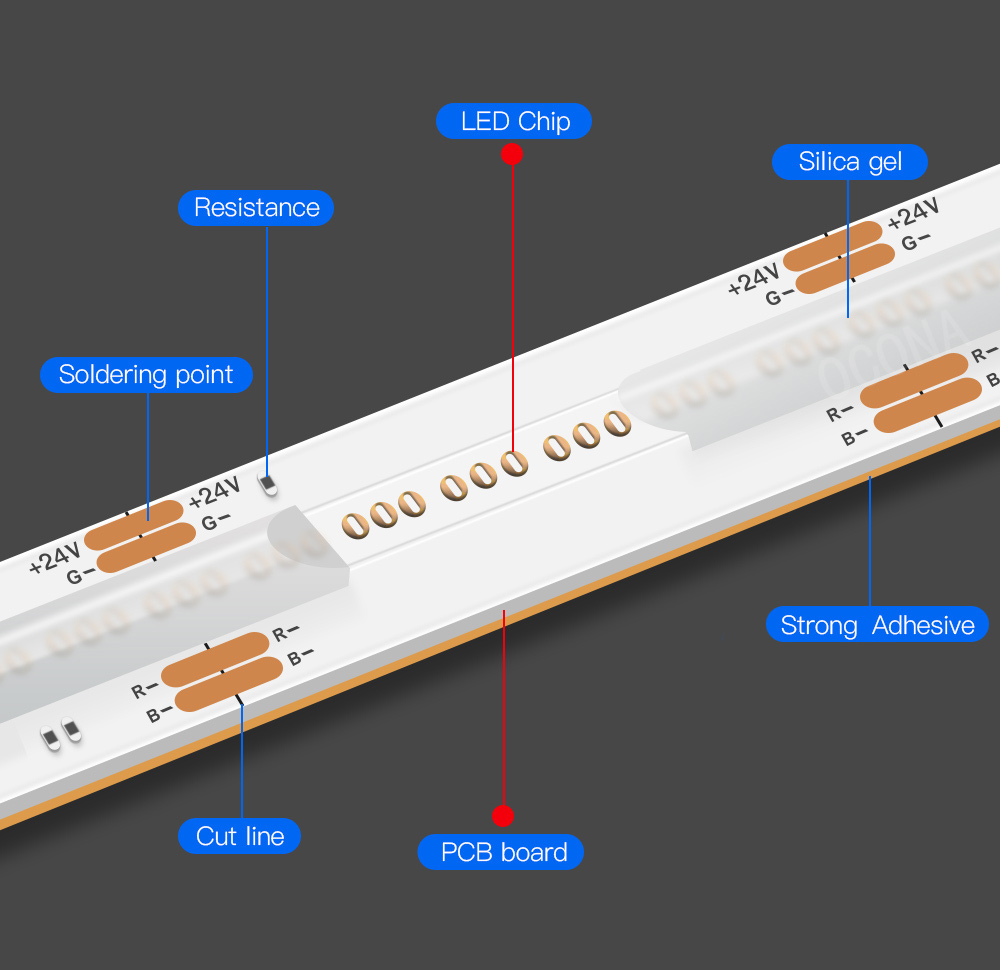

Chip on board (COB) is a method of circuit board manufacturing in which the integrated circuits (e.g. microprocessors) are wired, bonded directly to a printed circuit board, and covered by a blob of epoxy. By eliminating the packaging of individual semiconductor devices, the completed product can be more compact, lighter, and less costly. In some cases, COB construction improves the operation of radio frequency systems by reducing the inductance and capacitance of integrated circuit leads.

What is the advantage of COB LED Strip?

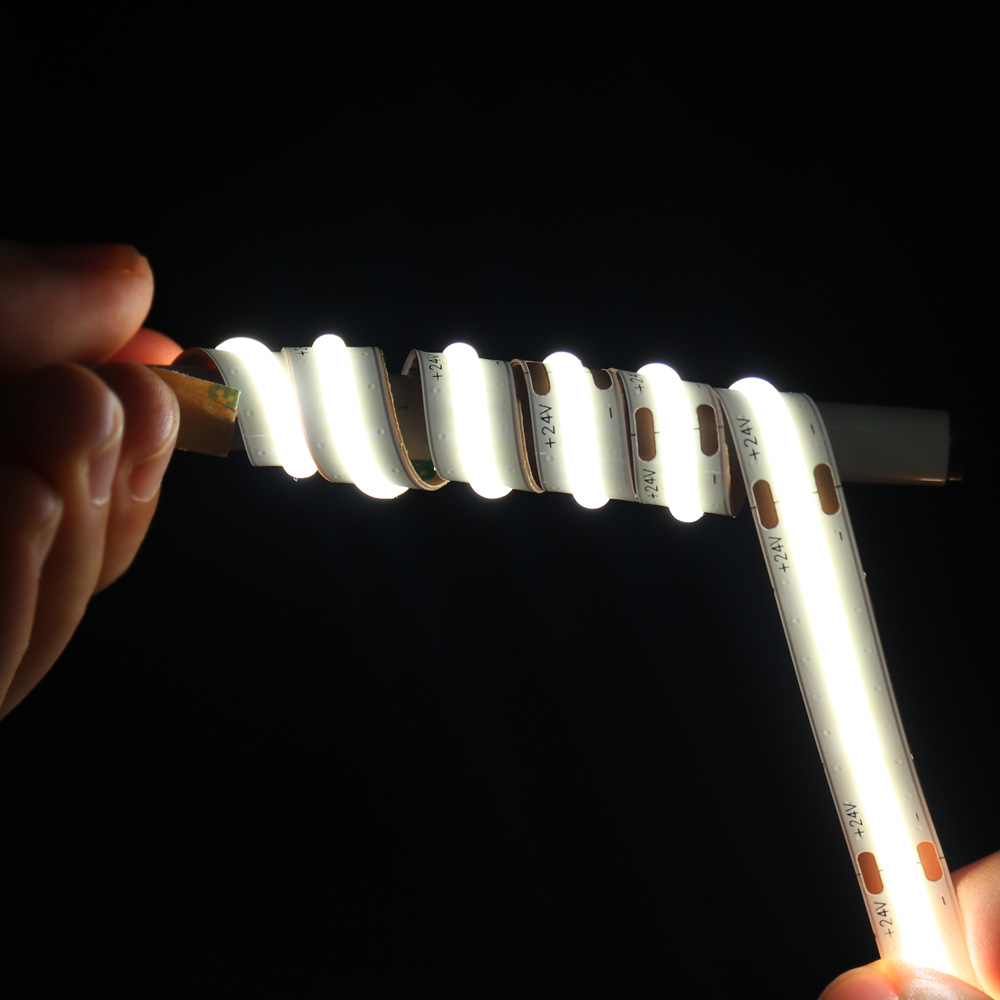

Continuous and Uniform, spot free, without dark area

Flexible, bending resistance

Cuttable. Can be cut and re-joined by soldering or fast connector.

SMD 2835 5050 LED strip has dark area, COB strip is a great improve for it.

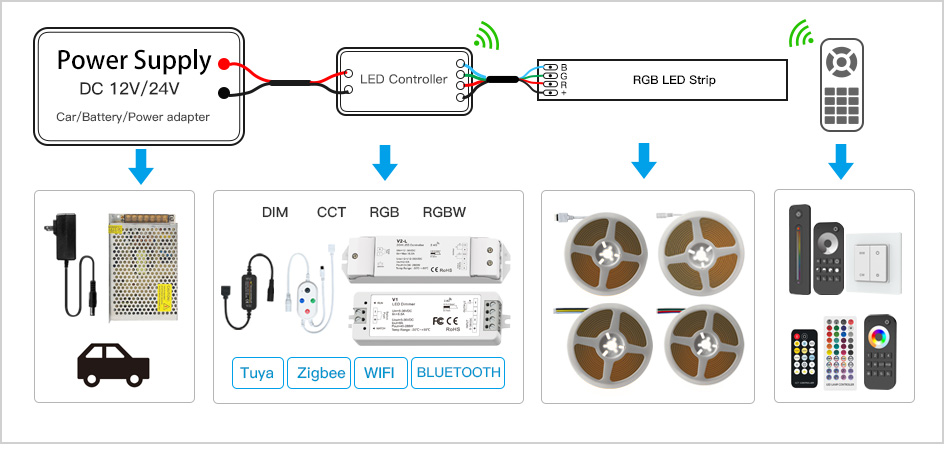

What do I need to use a COB LED strip?

4 issentials:

Power supply: Any DC12V/24V. power adapter, car or truck, battery, power transformer

LED Controller: to control brightness or color, light mode

Remote control: send singals to LED controller

COB LED strip:

Parameter explanation:

480LEDs/m

Means 480 LEDs unit per meter, the more the LEDs, the more uniform the strip light will be

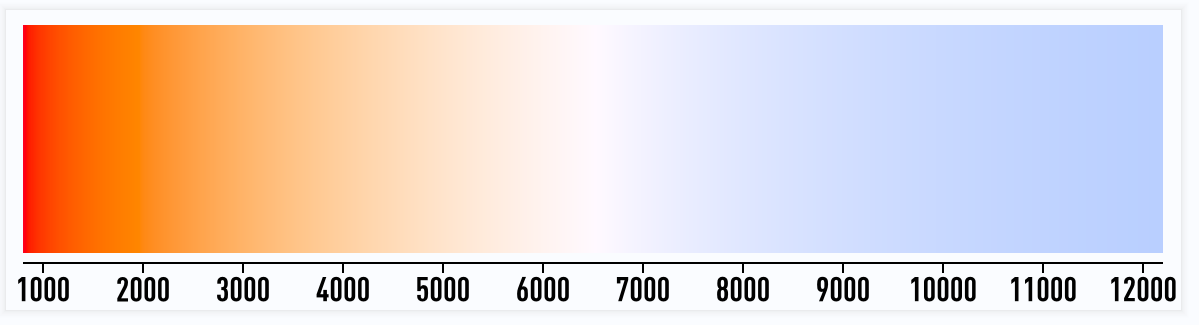

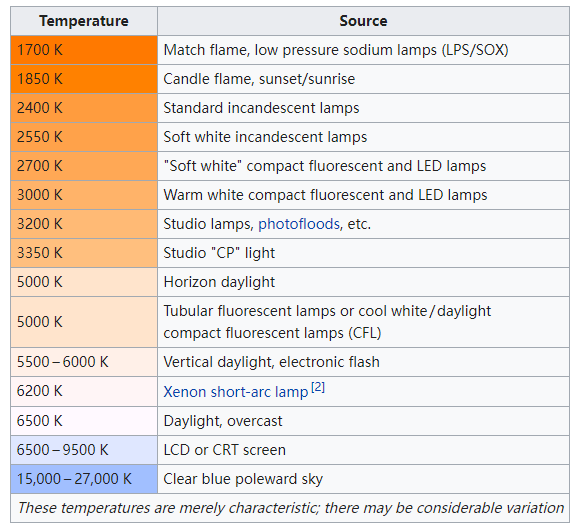

Color Temperature. 3000K 4000K 6500K....

See 3000K is warm white, 4000K is natural white, 6500K is cool white

CRI: Ra > 90

A Color Rendering Index (CRI) is a quantitative measure of the ability of a light source to reveal the colors of various objects faithfully in comparison with a natural or standard light source. Light sources with a high CRI are desirable in color-critical applications such as neonatal care and art restoration.

Numerically, the highest possible CIE Ra value is 100 and would only be given to a source whose spectrum is identical to the spectrum of daylight, very close to that of a black body (incandescent lamps are effectively black bodies), dropping to negative values for some light sources. Fluorescent lights range from about 50 for the basic types, up to about 98 for the best multi-phosphor type. Typical white-color LEDs have a CRI of 80 or more, our COB strip Ra> 90

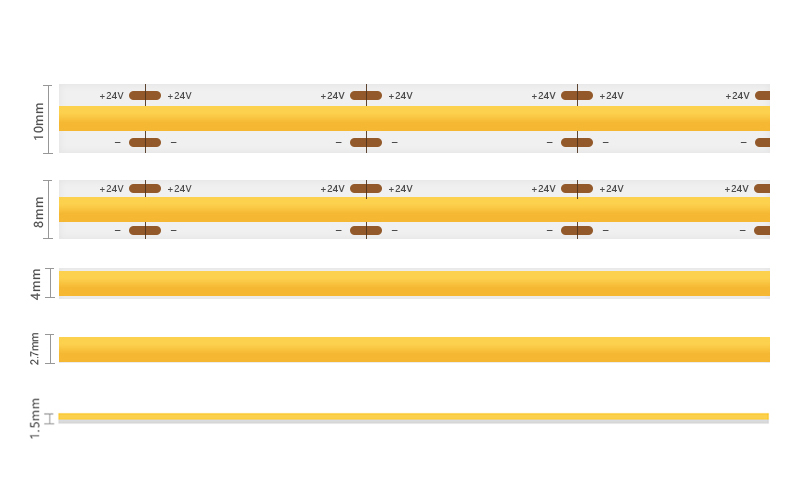

Strip Width: 2.7mm 4mm 8mm 10mm

Means the width of PCB, wide PCB will provide better heat dissipation, less voltage drop

2.7mm width, no edge, soldering pad on back

4mm width, small edge, soldering pad on back

8mm/10mm, with edge, soldering pad on edge

Rated power:

10W/m. COB strip consumes 10Watt per meter

Because of voltage drop(the decrease of electrical potential along the path of a current flowing in an electrical circuit.) for low voltage electronics, the far power end can not get enough voltage for driving, so the strip can not reach full rated power, unless increase the power injection point on every short length.

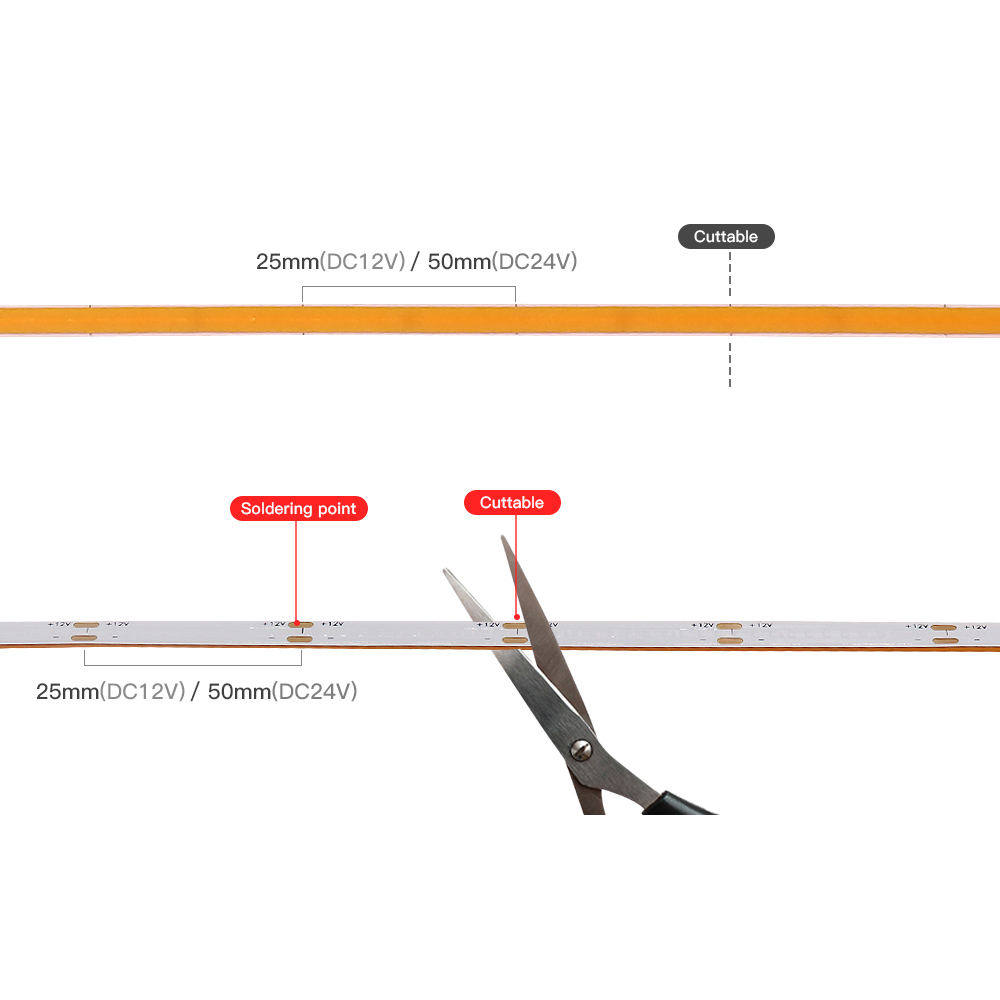

Cut Length:

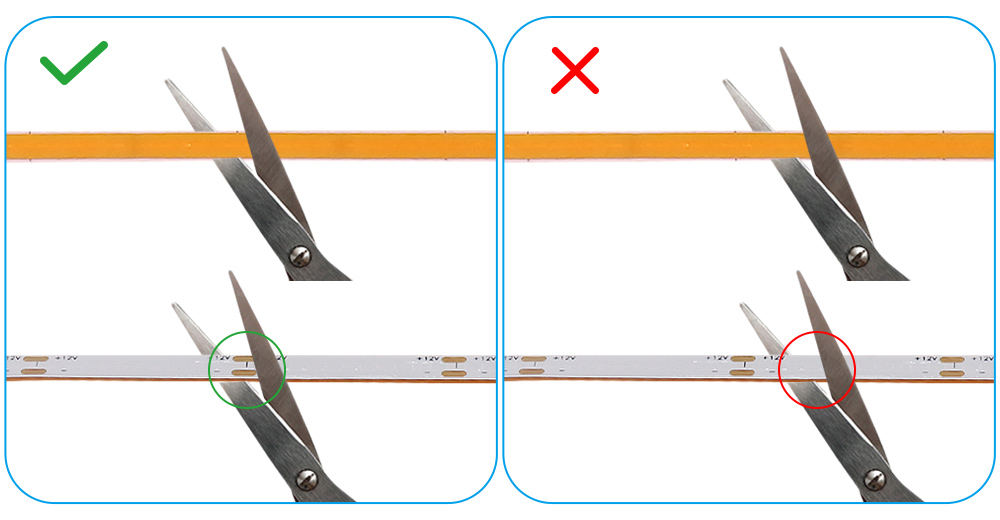

COB strip can be cut and re-joined by soldering or fast connector.

There is a black line(could be small) printed on PCB. There is where the strip can be cut.

If you do not cut on cut line, a small part between 2 cut lines will be broken. The other part will remain good.

What is DIM CCT RGB RGBW RGBWW RGBCW?

DIM, dimmer, usually for single color, you can adjust the brightness of strip

CCT, 1 strip with dual colors. Usually for white strip, our CCT strip can change from 2700K to 6500K

RGB, 1 strip with 3 colors, Red Green Blue. By the combination, theoretically 16M colors can be presented.

RGBW, 1 strip with 4 colors, RGB+W(White), could be warm white or cold white

RGBCW RGBWW, 1 strip with 5 colors, RGB+W(Warm white)+C(Cool white), with both warm and cool white

How to choose a outstanding COB LED strip lights?

How to wire COB LED strip?